![The art of metrology wins awards]()

Figure 1: The 3D InCites Award on display

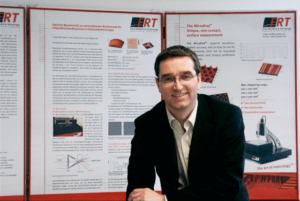

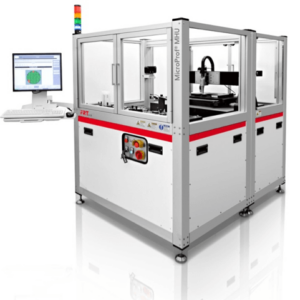

I first met Dr. Thomas Fries, Founder, and CEO of FRT, The Art of Metrology in 2016 at SEMI Europe’s 3D Summit in Grenoble. Fries became a big fan of 3D InCites, following us on social media, and sharing our content. Over the next few years, Fries and the team at FRT became more involved in the 3D InCites community, providing valuable insight for our tech round-up blogs, participating in the 3D InCites Awards, and winning the 2017 Equipment Supplier of the Year Award for the MicroProf (Figure 1). In 2018, FRT became a 3D InCites banner advertiser. In 2019, we expanded our partnership to include FRT’s sponsorship of Packaging IFTLE, Phil Garrou’s blog, so that Phil could continue delivering his advanced packaging message to his followers. You see, this is how a community works.

In recognition of being a 3D InCites Community Leader, we selected FRT, The Art of Metrology to be featured on the cover of the 2020 Yearbook. It’s a happy coincidence that 2020 also happens to be the 25th Anniversary of the FRT brand. It seemed a good time to tell the whole FRT story.

The FRT Brand Story

The story of the FRT brand is a very personal one for Thomas Fries. In its first incarnation, the FRT brand stood for “Fries Racing Team”, Fries’ motorbike racing team, which he started in 1981. Since then, it has come to mean a number of different things.

In the second incarnation of the FRT brand, the letters stood for “Fries Research & Technology”. After receiving a Ph.D. in Physics from the University of Bonn in Germany, Fries spent four years at Günther Systemtechnik GmbH building a department for scanning probe microscopy (SPM). SPM comprises scanning tunneling microscopy (STM), atomic force microscopy (AFM) and other probing technologies to resolve surface details down to the atomic level. In 1995, Fries purchased all the SPM equipment from Günther Systemtechnik, and along with two co-workers, parlayed his passion for motorbikes into a contract lab offering SPM services to a variety of manufacturing industries. In addition to SPM, they offered additional analytical services such as time-of-flight mass spectrometry.

![first generation art of metrology]()

Figure 2: First-generation MicroProf — tabletop version

“From the beginning, we focused on customer needs, offering measurement services primarily for our customers in the automotive and medical markets,” Fries recalls. If they didn’t have the necessary equipment, they rented it from the nearby Max Planck Institute, he said.

In those early years, FRT focused on automotive, medical, optical, and electronics markets. The team saw a need for a high-resolution tool that could measure very small areas and would bridge the gap between meters and nanometers. What Fries envisioned, was a multisensory tool that could be used to measure all surface dimensions. He calls it “bridging the gap from meters to nanometers.” In 1998, FRT’s first-generation multi-sensor tool was built, and the company evolved from being a service organization to an equipment supplier (Figure 2).

![]()

Figure 3: Thomas Fries, in the early days of FRT

“We never intended to build and sell tools, we just wanted them to use internally,” says Fries (Figure 3). “But then we realized developing a tool and scaling it was more interesting than doing high knowledge services.”

For the next eight years, FRT found its niche, developing and rolling out the second-generation multi-sensor tool, and continuing to target the automotive and optics, machining engineering and electronics markets, while also maintaining the contract business.

In 2006, as more pioneers of optical metrology entered the optics space, keeping prices low, Fries made the decision to break into the semiconductor market, as this space was being avoided by other players due, in part, to long turn-around times. In Fries’ opinion, the semiconductor industry offered an open playing field (Figure 4).

![The art of metrology on display]()

Figure 4: FRT showcasing its services at a trade show in 2006

“This was an opportunity to differentiate our company from the other players, and be unique by focusing on more complex technologies,” explained Fries. “Sure, it was risky, but there’s no fun without risk!”

To get started, FRT developed brand-new multi-sensor tools for the fab. In-house software developers wrote the interface themselves. As they were doing this, the LED industry was ramping up, and with it came a need to measure total thickness variation (TTV) of materials and exotic substrates. This called for a high-speed, high resolution, very accurate optical system, and FRT delivered. It quickly grabbed 100% market coverage of sapphire wafer metrology in Taiwan and 40% in China. It also served the traditional semiconductor and MEMS markets, but the market share was still small.

![]()

Figure 5: Metrology tool with material handling unit MicroProf® MHU

The crash of the LED market in 2011 came just as FRT had taken the step from R&D tools to production with fully automated tools in the LED market (Figure 5). As a result, 2012-2014 was a period of struggle for FRT’s sales organization, says Fries. But the company persevered and continued to develop fully automated third-generation metrology tools with a wafer handling system within an Equipment Front End Module (EFEM) for the semiconductor and MEMS markets. By 2015, it had recovered thanks to traction in its original markets: automotive and optical, and big European customers.

FRT: The Art of Metrology

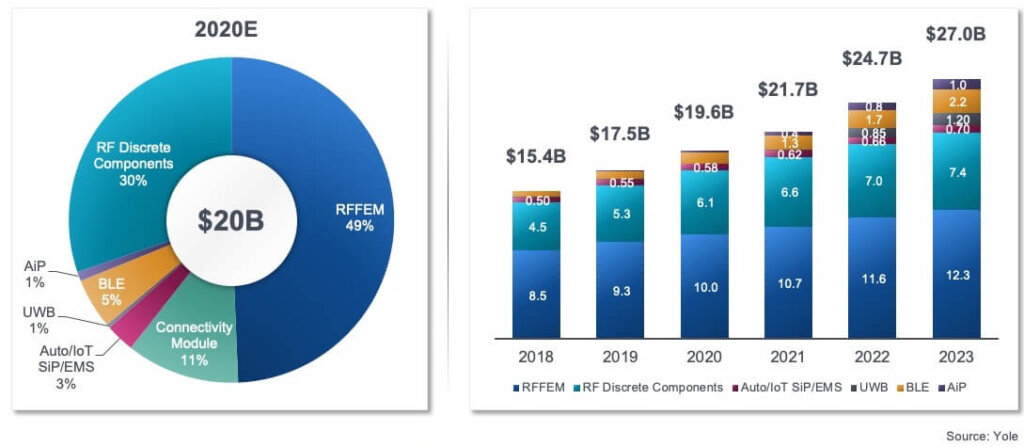

2016 brought the third incarnation of the FRT brand: FRT, The Art of Metrology, along with new assets and a logo change. 80% of its tools were being sold in the semiconductor and MEMS spaces. The company also broke into the advanced packaging market, succeeding with top-tier integrated device manufacturers (IDMs) and memory makers in the USA and Asia.

With the new brand came an enhanced idea about marketing, as well as a change in attitude about metrology. The company focused on its nimbleness and flexibility. When working with customers, Fries and the whole FRT team took a holistic approach, examining each project from the point of view of the customer, and investing in new technology development (Figure 6).

![]()

Figure 6: The Wall of Fame at FRT Headquarters

“From 2016-2019, FRT, The Art of Metrology, was one of the companies with the highest annual growth rate,” said Fries. “It became clear that if we were going to continue on this trajectory, we needed a strategy.” Part of this was to create a demo facility and open a new subsidiary, FRT of Taiwan. But expanding a global footprint very fast can be difficult for a small company. Multiple advanced orders can create a cash flow crunch. It was time to consider other options.

FRT: A FormFactor Company

In what can only be described as one of the fastest mergers in recent semiconductor history, in November 2019, FRT, The Art of Metrolgy, was acquired by FormFactor in a simultaneous signing and closing. As part of the deal, FRT will maintain using its well-established brand and operate as a FormFactor company.

![]()

Figure 7: I visited with Amy Leong and Mike Slessor at FormFactor’s HQ in Livermore, CA

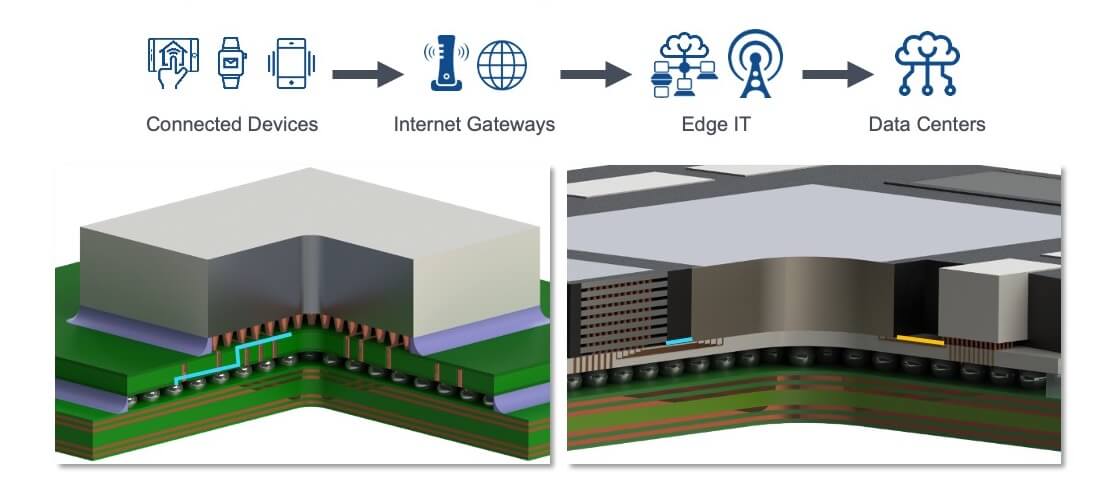

Ten years ago, FormFactor was primarily a DRAM probe card provider, with a very concentrated and volatile demand profile. In 2012, the company began to diversify by acquiring MicroProbe, the number one supplier of advanced non-memory probe cards, to expand its presence in the foundry and logic markets. In 2016, the company acquired Cascade Microtech, which brought RF probe cards and engineering systems. With the FRT acquisition, the goal was to expand FormFactor’s reach into optical metrology focused on the advanced packaging space, explained Mike Slessor, CEO, FormFactor (Figure 7).

“Advanced packaging is driving our business,” said Slessor, “This is a growth area in the industry, and we are dedicating more resources to roadmap innovation in serving advanced packaging applications.”

Slessor, Fries, and Amy Leong, CMO and VP of M&A for FormFactor all agree that the two companies are a natural fit. FormFactor is a leader in the electrical test for the semiconductor and advanced packaging industry, while FRT’s core competencies are optical metrology and inspection.

“FRT has great technology with good adoption, but to be a world-class supplier, you need the infrastructure and ability to support it globally. As a small company, it’s not easy to grow that organically because it’s expensive to build that infrastructure; but it’s an infrastructure and set of customer relationships that FormFactor already has,” said Slessor.

“We wanted to have a global footprint but lacked the resources to hire and do more development,” Fries explained. “This is the best situation because FormFactor is not active in the optical metrology business. All others (competitors) would have squeezed us out, and that would have been the end of FRT. Now, we are a new business unit. We have the chance to perform. They want to build up the FRT business.”

“We took a broad look at the metrology players, and for a variety of reasons, FRT bubbled up,” explained Leong. “The transition was easy because there was no overlap in technology offerings.” FRT’s focus on metrology and inspection for advanced packaging and niche applications such as silicon photonics was a key selling point, explained Leong. Others included size, scale, and customer engagements, including customer pull for hybrid solutions. (In a happy coincidence, Leong says she first learned about FRT as a company from their presence on 3D InCites.)

The Next Era

January 2020 kicked off a new era for FRT as the company added defect inspection tools for wafer applications to its portfolio. This new capability was customer-driven, said Fries. A customer had a need, and FRT developed the capability.

The modular system is capable of defect inspection down to one micron. It uses image sensing technology to find scratches and particles in wafer samples and then uses metrology to analyze the defect to see if it is a latent or killer defect. It performs full wafer mapping and different types of inspection.

By first looking for rough defects and then only zeroing in on trouble spots with 3D metrology, throughput is increased, explained Fries. The idea is to identify “golden die” and compare it to those with defects.

Customers will be able to order either full inspection systems or combine both metrology and inspection into one tool. Integrating both capabilities into one platform allows for the same software that are components to be used on all tools.

“This offering is unique to FRT. We are the only manufacturer on the market that provides these capabilities in a single platform,” said Fries. “Others have different platforms for inspection and metrology.”

The Art of Metrology Culture

After spending a day at FRT’s headquarters near Cologne, Germany, and meeting members of the team from the executive management to administrative support, it’s easy to see what makes it such a great place to work. The company fosters a diverse and inclusive workplace, with employee representation from 17 different countries of origin. 33% of the workforce are women, the staff is between the ages of 23 and 60 years. The young people bring in new ideas, and the older employees mentor them. In this way, they learn from each other.

In addition to hosting a summer barbeque and Christmas party, there is FRT Day, a team-building event featuring activities and sports. Community outreach includes offering training to primary school teachers along with materials to help teach physics and science to children. Lastly, the company hosts a Technology Night during which they open their doors to the community from 6 pm to midnight so people can come and learn about what they do. This gives students the opportunity to see where they could work someday, explained Sarah Trompetter, FRT’s marketing, and communications manager.

As Dr. Jürgen Koglin, head of applications at FRT notes, the company has always had a family-like atmosphere. “We were a small family at the start. Now we’re a big family,” he says. Koglin joined in 1997, just as FRT was getting started. He knew Fries from his time as his student at the University of Bonn. After receiving his Ph.D. in Physics from the University of Muenster, he joined the company as employee #7. As a result, he was very involved in company decisions. “Everyone was involved in the beginning,” he recalls.

All tool development at FRT is application centered. While they begin with standard tools, the last 5-10% is custom configured. Koglin and his team of five work with customers to perform test measurements and feasibility studies on customer samples to determine what type of sensor, measurement, and instrument is suitable for the customers’ tasks. While the work is technical, the team works closely with the sales team to ensure they recommend the best combination to the customer.

Koglin says that over the years as they work on more intricate technologies, the solutions become more complex. There are many types of applications that must be solved with one tool and different sensor types, but that’s what keeps his job so interesting.

As a department head, Koglin gets to build his own team. He says he looks for motivated people who can think on their own and develop solutions, but also work well on a team, as all projects require collaboration. “It takes about a year to become involved in the techniques,” he said. “So we look for people who will stay at least 3-5 years.”

Bastian Tröger, product management, is another FRT veteran who came to the company straight from academia. Armed with his master’s thesis, in which he constructed a tool for measuring diffraction efficiency, he joined FRT in 2007 as part of the development team and worked his way to product management. He’s been a team leader in PM since 2017.

Tröger reminisced about his days in the cleanroom and how exciting it was as new products were developed. Today his main focus is on typical product management tasks. But he also enjoys working with the field engineers, supporting on-site tool acceptance and application development at customer facilities.

What has kept him there for more than a decade? “If you work here, it’s not a routine job. It’s different every day and there are always new challenges,” he said. “We’ve got a good, collaborative team and we know each other well.”

What’s Next for FRT, The Art of Metrology?

25 years is a good chunk of time in an industry that is barely over 50 years old. In that time, FRT has established a strong foothold in process control for heterogeneous integration technologies. Going forward, as device reliability becomes more and more critical, FormFactor will provide the muscle to take this nimble player to the next level without sacrificing its flexibility, integrity, or company culture. I’m excited to see what the next quarter-century has in store.

The post 25 Years Perfecting the Art of Metrology appeared first on 3D InCites.

, which provide world-class process development services, and serve as open access innovation incubators for customers and partners across the microelectronics supply chain. Through these centers of technology excellence, EVG helps customers to accelerate technology development, minimize risk, and develop differentiating technologies and products through the implementation of nanoimprint lithography and heterogeneous integration, respectively, while guaranteeing the highest IP protection standards that are required for working on pre-release products.

, which provide world-class process development services, and serve as open access innovation incubators for customers and partners across the microelectronics supply chain. Through these centers of technology excellence, EVG helps customers to accelerate technology development, minimize risk, and develop differentiating technologies and products through the implementation of nanoimprint lithography and heterogeneous integration, respectively, while guaranteeing the highest IP protection standards that are required for working on pre-release products.

and Taiko

and Taiko